JPM Industries Limited

Company Feautures

JPM Industries Limited (Formerly known as Jay AutoComponents Ltd.) is an ISO/TS 16949:2016 certified business entity that caters to wide range of automotive products for its esteemed clientele. We have five state-of-the-art manufacturing plants in ( Manesar and one each in Gurgaon, Roorkee and Pune, Bhiwadi) with a combined strength of 1500 employees across the nation to deliver quality driven products

Products

- Injection Moulded Parts.

- Painted Parts.

- Laser Marking

- LED

- Energy Meter

- Plated Parts.

- Automotive Assembly Parts.

Facilities

- Injection Moulding

- Vertical Injection Moulding

- Automated Paint Shop (with conveyor)

- PAD Printing

- Laser Marking

- Paint Shop

- Electroplating on Plastics

- Testing

We have dedicated Assembly Lines for every product that we manufacture. This ensures isolation and insulation of one process from another. This also helps in reducing machine errors, human errors and ensures proper coordination between the different stages of work.

Since we are a technology and quality-driven business conglomerate, it is imperative for us to deliver high quality product everytime to our clients. As such, we have following Testing Facilities installed in our plants:

- Head Lamp Levelling Test Machines

- Control Panel Base Test Machines

- Control Panel Base Test Machines

- Heater Switch Test Machines

- Hazard Switch Test Machines

- TTRs

- Humidity Chambers

- Paint Thickness Testers

- Adhesion Testers

- Gloss meters

- Desiccators for E10 Testing

- Air Velocity Testers

- Hugmen Gauges

- Salt Spray Chambers

- Colour Matching Cabinets

- Conical Bend Testers

We have the following designing facilities installed in our organization to ensure top notch quality products:

- Auto CAD

- Centralized Design and RnD Station.

We have Semi-Automatic and Air-Shower Manpower System with Manper Movement in our plants. Please follow this link for more details.

- MACHINES - 12

- Components

- Wiper (upper) - 2

- Passenger Air Bags

- Knob Horns

- Shutter Keys

- Assembly

- Lighting Assembly

- Wiper Assembly

- Volume per day-100000 comps./day

- Employee strength- 50

Products

Injection Moulding is a manufacturing process for producing parts by injecting material into a mould. We have an excellent setup regarding the processing of our requirements for the same. Please visit this link for more details:

- TOTAL MACHINES –54NO’S

- CAPACITY

- 20 T – 01

- 40 T – 02

- 50 T – 03

- 80 T – 01

- 85 T – 01

- 90 T – 15

- 100 T – 11

- 120 T – 12

- 130 T – 02

- 150 T – 12

- 160 T – 01

- 180 T – 02

- 200 T – 01

- 250 T – 05

- 260 T – 02

- 280 T – 01

- Volume 60 LACS comps./month

LED

Our largest consumer base for LEDs comprises of Home Users, especially those who prefer ‘Energy Star’ rated products that use 75% less energy and last 25 times longer than a normal light bulb.

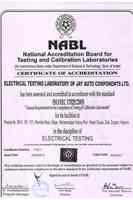

Awards Certifications